Dekati - Metal and polymer 3D prints in finished products

Customer need

The cooperation between 3DStep and Dekati started in 2016. Dekati was one of the first long term partners of 3DStep. The collaboration started with product development prototypes and getting to know 3D printing technology. Now, the collaboration has resulted in 3DStep being Dekat’s contract manufacturer, supplying metal and plastic printed components directly to the assembly for installation in end products.

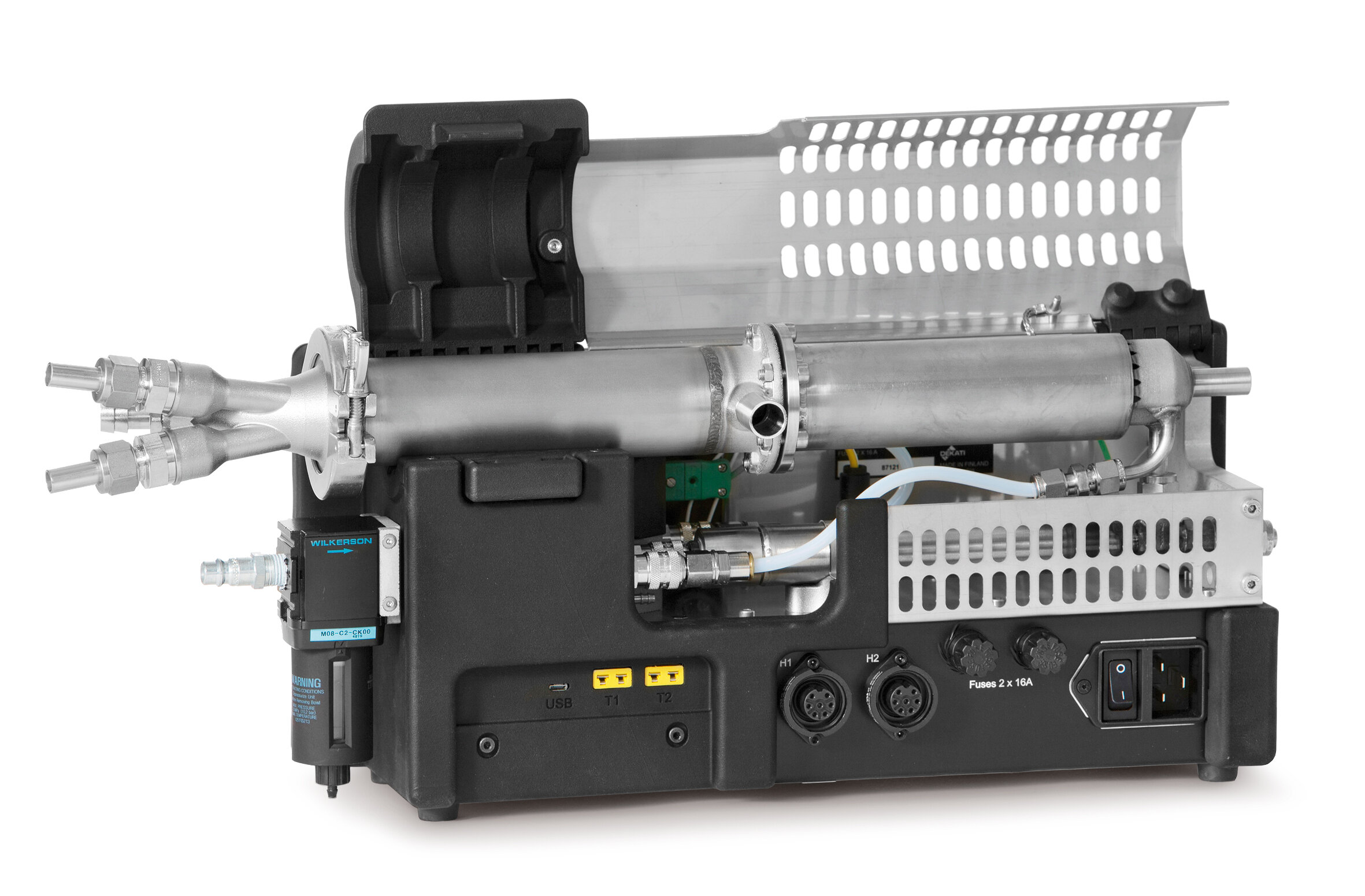

Dekati's products and production volumes are favorable for the utilization of 3D printing. Products contain complex components and processes. In addition to this, the volumes are reasonably small. The eDiluter has the most potential for 3D printing (Figure).

Benefits

The products of the previous generation were built on the terms of traditional methods. An example of this is the Dekati FPS used in the same applications as eDiluter (picture). The product included a lot of complex piping and assembly work, as well as welded and machined structures. The product had extreme dimensions of 560 x 410 x 310 mm and weighed 30 kg. In addition to this, there was a separate diluent (Figure). Using a new way of designing and utilizing 3D printed components, the dimensions of the product were reduced to 205 x 168 x 520 mm and the weight dropped to 7.3: kg, with the diluent integrated.

An older generation device with extreme dimensions of 560 x 410 x 310 mm and a weight of 30 kg

The new generation eDiluter with dimensions of 205 x 168 x 520 mm and weight of 7.3: kg

Solutions

The polymer mechanics of the product are made by MJF technology from PA12 material, which is dyed black and coated with a micro-coating. The micro-coating protects parts from moisture and dirt, and makes the surfaces easier to clean.

Metal 3D printing has been utilized in many places. Complex tube and flow components are printed from 316L and AlSi10Mg materials. With 3D-printed components, time-consuming assembly and installation work was minimized.

The solutions led to a radical reduction in weight and physical size. The products also utilize hybrid manufacturing. The 3D printed metal components stick to the machining platform in their substrate, after which the finished parts are wire sawed off the platform.

Most importantly, however, the performance and usability of the products are better than the previous generation.

Dekati’s story demonstrates that design and product development are key to making the most of 3D printing. Customer product development needs to be supported by a 3D printing professional who can guide designs for better 3D printing by making process and material knowledge available to the customer.

Our mission is to create the best conditions for the utilization of 3D printing, and the development work done with Dekati is a great proof of this.

” Collaboration with 3DStep has been straightforward. The dialogue in both directions has gone well.”

Leo Holma, Dekati Oy

Dekati Ltd. is a world leader in the design and manufacture of innovative small particle measurement solutions. Dekati has almost 30 years of experience in supplying measuring devices, sensors and complete small particle measurement solutions for a wide range of environments and conditions. Dekati's turnover in 2020 was € 3.8 million and it employed more than 20 professionals. You can read more about Dekati's solutions www.dekati.com.