A professional's guide to sourcing 3D printing services

As an industrial procurement professional, you've likely heard that 3D printing (Additive Manufacturing - AM) offers fast and flexible solutions for manufacturing spare parts, prototypes, and small production runs.

But do you know how to integrate this technology effectively into your sourcing strategy to maximize its value and mitigate risks? This guide is designed to help you navigate the landscape of 3D printing procurement.

When to choose 3D printing?

3D printing excels in producing one-off parts, small and mide-size series, and highly customized components. Consider it a strategic option when:

You need hard-to-find or low-volume parts quickly, such as obsolete spare parts for legacy machinery where original tooling is gone, custom jigs and fixtures for your assembly line, or highly specialized components for R&D projects. 3D printing is often a more suitable and cost-effective choice than traditional manufacturing, especially when parts are not worth stocking in large quantities, thereby reducing inventory costs.

Rapid prototyping is essential to accelerate your product development cycle and get new products to market faster.

You require bridge manufacturing to fill a gap before mass production tooling is ready.

Design changes need to be implemented rapidly without the significant additional costs and lead times associated with modifying traditional tooling.

You're looking at Total Cost of Ownership (TCO) advantages, such as eliminating or drastically reducing tooling investments for small series, or the potential for part consolidation (designing a single 3D printed part to replace a multi-part assembly, saving assembly time and simplifying inventory).

Choosing the Service Provider: Beyond the Basics

Key criteria for procurement include reliability, quality, and cost-efficiency. When selecting a 3D printing service provider, go deeper than surface-level checks:

Proven expertise & technology fit: Select a provider with extensive, demonstrable experience in various materials (plastics, metals) and relevant technologies (e.g., SLS, SLM, MJF). Ensure their technological capabilities align with your specific part requirements (accuracy, strength, material properties).

Robust quality management systems: Look for certifications like ISO 9001 (quality) and ISO 14001 (environmental). However, dig deeper:

Process control & repeatability: How do they ensure consistent part quality from the first print to the hundredth? Ask about their specific process monitoring, in-process quality checks, and validation methods.

Material expertise & sourcing: Beyond listing materials, verify their knowledge of application-specific material selection. How do they ensure the quality, consistency, and traceability of their raw materials (e.g., powder batch control, handling of hygroscopic materials)?

Comprehensive post-Processing capabilities: The initial print is often just one step. Assess their in-house and trusted subcontracted post-processing capabilities (e.g., heat treatment, CNC machining for critical features, surface finishing, dyeing, vapor smoothing, infiltration). Understand how these affect lead times, cost, and quality control.

Scalability and Redundancy: If your pilot project is successful, can the supplier handle increased volumes or more complex projects? Do they have multiple machines of the same type or contingency plans to ensure business continuity?

Design for additive manufacturing (DfAM) support: A true partner will offer DfAM expertise, proactively suggesting design modifications to optimize your parts for printability, reduce material usage, improve performance, and lower costs.

Technical communication & transparency: Your provider must be capable of clear, unambiguous technical communication and provide realistic delivery schedules.

Essential documentation: Ensure they can provide full material traceability (including certificates of conformity for raw materials), comprehensive quality inspection reports (e.g., First Article Inspection Reports - FAIR), and documentation of any agreed-upon testing.

References & case Studies: Ask for references from similar projects or industries.

3D printed parts are reliable

Modern additive manufacturing technologies, when expertly managed, have reached a level where they can consistently deliver mechanical strength, dimensional accuracy, and material performance. For specific applications, these can be on par with, or sometimes even exceed, those of traditionally manufactured parts. The aerospace, automotive, medical, and defense sectors now rely on 3D printed parts in mission-critical applications. Certified 3D printed metal components, for instance, are already flying in aircraft and orbiting in satellites.

Achieving this reliability isn't automatic. With the right material selection, design optimized for AM, validated process controls, and appropriate post-processing techniques, 3D printed parts can meet stringent quality and durability requirements. Be aware that some properties (e.g., anisotropy in parts from certain processes, or as-printed surface roughness) can differ from conventionally made parts and must be understood and accounted for in your design and specification phase. When sourcing from a qualified provider who understands these nuances, you can expect reliable, repeatable results and full compliance with your engineering requirements.

Benefits of partnering with an experienced 3D supplier

A trusted, experienced 3D printing partner, such as 3DStep Oy, does more than just print parts. They become an extension of your team:

Strategic collaboration: They assist with design optimization (DfAM), advise on optimal material selection for your application, and support your quality assurance process from specification to final inspection.

Risk mitigation: Beyond robust IP protection and data security (essential in sectors like defense), a good partner helps mitigate supply chain risks by offering an alternative to traditional manufacturing, especially for obsolete parts or those with volatile supply chains. They also help manage quality risks through transparent processes and agreed-upon inspection criteria.

TCO reduction & supply chain optimization: Additive manufacturing can significantly reduce warehousing needs (digital inventory), minimize material waste (additive vs. subtractive), and shorten complex supply chains. This can lower your total cost of ownership while improving supply chain resilience and agility, enabling faster time-to-market for your organization's products.

Obsolescence management: AM provides a lifeline for acquiring obsolete parts where original tooling is unavailable or MOQs are prohibitively high, reducing equipment downtime.

Integration support: Forward-thinking providers can discuss how to best integrate 3D printed parts into your existing workflows, perhaps even touching on digital inventory management within your ERP systems.

Making 3D printing a strategic procurement tool

3D printing is a powerful tool in the modern procurement professional's arsenal. When used strategically for the right applications, and by partnering with a competent, experienced, and transparent supplier, such as 3DStep Oy, it helps you deliver significant value, flexibility, innovation, and resilience to your organization.

TIP: 3DStep provides an easy-to-use online service for quotations and orders!

DOs

Define clear technical specifications (material grade, critical dimensions and tolerances, surface finish, post-processing needs, relevant standards) and provide high-quality CAD files.

Check for relevant certifications and inquire about their specific quality management and process control procedures.

Ask for reference cases and examples of similar parts they have produced for your industry or for comparable applications.

Require comprehensive quality documentation (material certifications, inspection reports, certificates of conformity). Clearly define acceptance criteria.

Include robust IP protection, confidentiality (NDA), and data security clauses in all contracts.

Pilot test with a single or small batch of parts to validate the supplier and process before scaling up.

Confirm the supplier’s capacity, typical turnaround times, and their ability to scale if needed.

Monitor delivery reliability, part quality, and maintain ongoing communication throughout the project.

Discuss and agree on ownership and responsibility for design files, especially if the supplier provides DfAM services.

Consider Service Level Agreements (SLAs) for recurring orders, covering lead times, quality metrics, and communication protocols.

Assess the supplier's DfAM capabilities and their willingness to collaborate on design optimization.

Inquire in detail about their material sourcing, handling, traceability, and post-processing capabilities.

DON'Ts

Don't assume all 3D printing providers or technologies offer the same quality or are suitable for your specific application.

Don't overlook the critical importance of post-processing and finishing, as these can significantly impact performance, aesthetics, and cost.

Don't ignore responsibilities for design errors or ensuring tolerances are clearly specified and achievable with the chosen process and material.

Don't forget to compare the total cost of ownership (TCO), not just the per-part price. Factor in tooling savings, reduced inventory, faster lead times, etc.

Don't share sensitive 3D models or technical data without a Non-Disclosure Agreement (NDA) in place.

Don't underestimate the importance of aligning on quality inspection methods, standards, and critical-to-quality (CTQ) features early in the discussion.

Pekka Ketola from 3DStep will be in Nordic UN Procurement Seminar June 10-11 2025, Copenhagen. Let’s meet and talk!

tel. +358 50 5534783

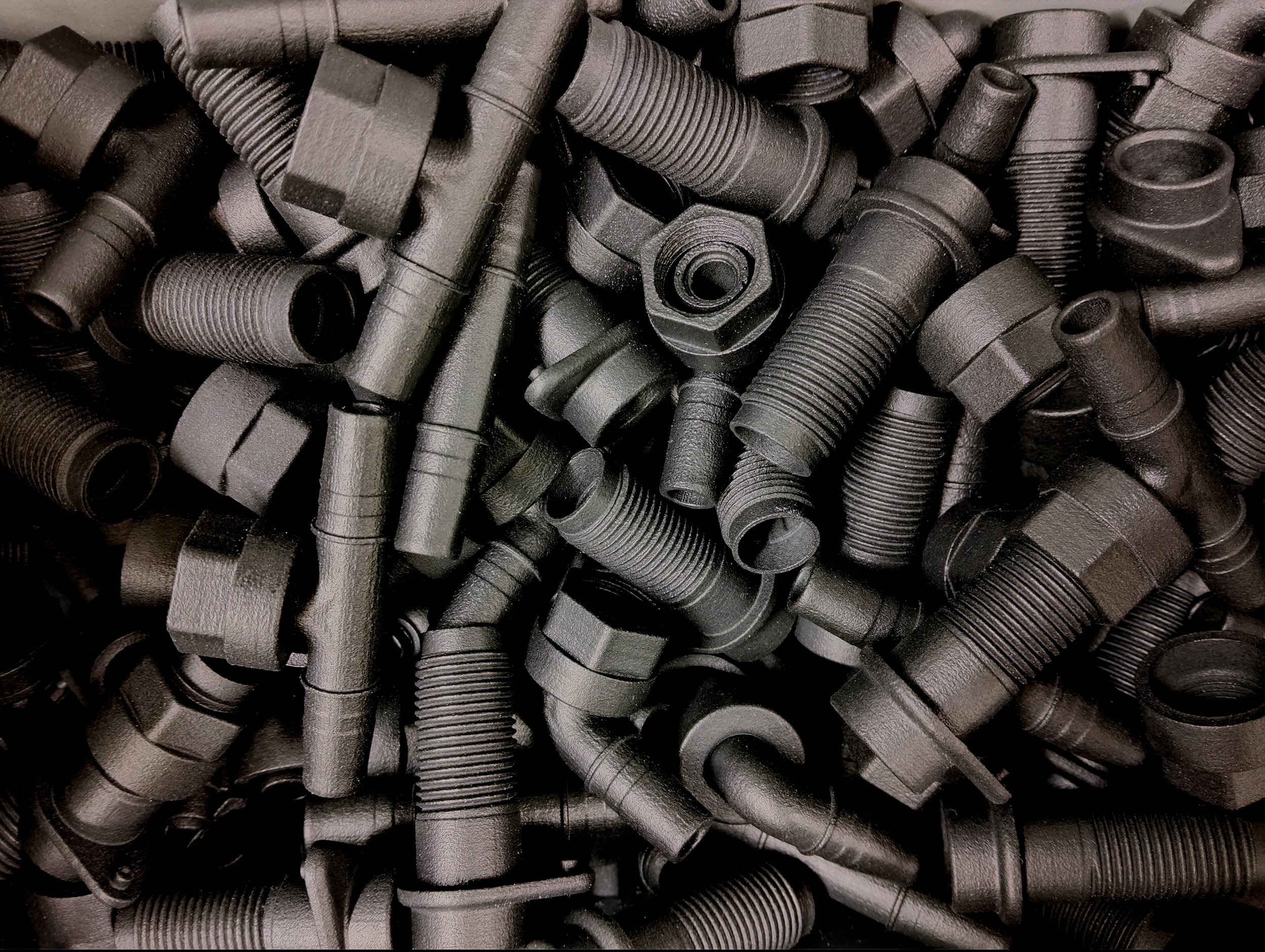

Serial 3D printing by 3DStep, material PA12.