People in additive manufacturing: Starring EBBAMS and TUT – the Egyptian robot

Who are the people and teams advancing additive manufacturing and what are their stories? What inspires them? How do they see the future of AM? In this serie of interviews we will meet some of the amazing persons who have given their heart into additive manufacturing and 3D printing.

Extraordinary innovation with 3D printing in Egypt

EBBAMS (Egyptian British Bureau for Additive Manufacturing Services) is the first private sector 3D printing bureau in Egypt (www.ebbams.com). The company leads the industrial 3D printing evolution in Egypt with extraordinary collaborative practices and innovation. 3DStep had an honor to interview the team to learn about the current state and to hear the story of 3D printed robot that speaks Egyptian.

Story of EBBAMS

EBBAMS offers additive manufacturing, design and training services for the industrial communities in Egypt. It was established in 2019 with founders and investors who have intensive business experiences in a variety of industries. EBBAMS started 3D printing services with FDM technologies, and extended the services rapidly to resin technology and SLM metal additive manufacturing.

The company empowers the different businesses to re-imagine the way they design and manufacture their products.

We are aiming to change behaviour and knowledge about 3D printing in Egypt, and to increase understanding of metal additive manufacturing in particular, says Youssef Abdel, chairman & CEO at EBBAMS.

The leading person is Youssef Abdel Khalick. He has unique capability to inspire people to achieve the impossible and to cocreate in creative ways.

Story of TUT, the first Egyptian 3D printed robot

One day a reporter from DMC media company asked if EBBAMS could create an artificial colleague for him. EBBAMS took the challenge and started to create an Egyptian robot that would lead the way for future droids and would provide a powerful learning experience for the team.

Three teams were established. One from the customer (DMC) to own the project, a production team to create the robot (EBBAMS) and a programming team to design the software and user interfaces.

The making of TUT was a huge innovation effort with lots of challenges, trials and victories. The multidisciplinary teams worked hard to find solutions and to learn quickly. Lot of the solutions needed to be built from scratch without previous experience in building a robot. Some ideas were copied and improved from Internet sources.

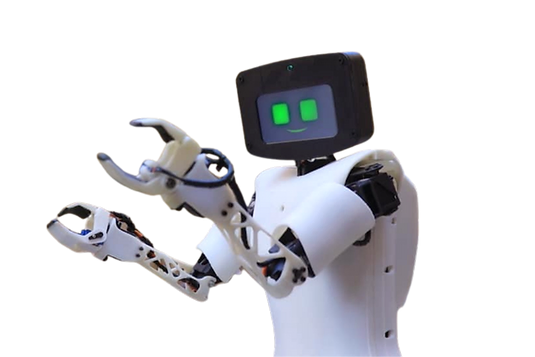

TUT - 3D printed Egyptian robot

Should the robot look like Egyptian or have a modern outlook? The team put major effort in the usability and user experience. They wanted the robot to be usable by anyone and to mimic Egyptian dialect properly. Also the appearance was important. The robot should look friendly and at the same it should be able to physically incorporate all the needed components, batteries included, in a great design.

The client wanted the robot to walk. This wasn’t an easy task! The team needed to find combined mechanical and software solutions to make this happen and to perform well in different contexts. A bunch of sensors, optical scanning and vision systems were needed.

Pushing the team to its limits, the project succeeded! TUT saw the daylight and appeared in the streets of Cairo in 2021.

From innovation and cocreation perspective this project is an important reference for us all. It united stakeholders from several organisations for the same mission and invited professionals and academics to work together with students.

How the story continues?

3D printing industry in Egypt has taken the first important steps led by EBBAMS. According to Youssef Abdel Khalick, the future efforts will have impact on Egyptian business, informatic communities and education to increase the activities and national businesses around 3D printing.

TUT project opened the doors to the making new specie of friendly robots. 3D Droid, a concept developed by EBBAMS, aims to create customizable robots for a variety of use cases, for example in banking, hospitals and construction.

3DStep wishes a great and rewarding future for Egyptian additive manufacturing!

Warm thanks for the interview:

EBBAMS Team: Youssef Abdel Khalick, Chairman & CEO, Sarah Youssef, Managing Director, Osama Kamal, Senior Technical Engineer, Hala Salem, Technical Engineer, Yumna Salama, Marketing Manager, & Salma Seyam, Marketing Specialist.

ElHaiez MakerSpace Team: Khaled Eyada, Team Leader-Coding, Doaa Nasr, Mobile App Developer, Mohamed Hesham, Embedded Systems & AI Developer (senior year school student), & Shahd Yasser, User Interface Designer.