People in additive manufacturing: Laurent Bernadac

Who are the people and teams advancing additive manufacturing and what are their stories? What inspires them? How do they see the future of AM? In this serie of interviews we will meet some of the amazing persons who have given their heart into additive manufacturing and 3D printing.

Inventor, musician and 3D printing forerunner

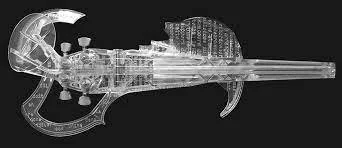

Laurent Bernadac is a french violinist who develops a new approach of the electric violin as a ‘real’ unique instrument. He is also a guitarist and a drummer. Engineer in mechanical design and energy, he is the designer and the creator of the 3Dvarius, the electric violin fully created by 3D printing technology.

How You and 3D printing met for the first time?

I met 3D printing technology during my engineering studies at the INSA Toulouse, France. But at the beginning it was just the FDM technology without any possible applications for violin industry.

Then, I started to meet some different suppliers to adjust and choose the right technology at the right price (SLA).

What inspired You in 3D printing?

3D printing technology allows to produce impossible shapes and organic designs to improve the playability and the lightness of the instrument. There are less limits during the design process and this was the most inspiring thing to me.

3Dvarius

3Dvarius is the name of the first violin I designed. Its also the name of the company we ran since 2016 to develop these new instruments.

At the beginning I wanted to have a “personal and unique” electric violin for me as violin player. So I started to do some research and studies on this way. The instrument production was something really new to me. I was just violin player and mechanical engineer at this time.

Then I came across different ideas and process to obtain the first final violin (manual carving, CNC carving, metal 3D printing and finally SLA technology). (Learn how 3Dvarius is made).

Printed as a single piece, the 3Dvarius Electric Violin departs from traditional musical instrument production technology. This particularity ensures a perfect accuracy of the audio spectrum.

The 3Dvarius was designed to facilitate the transition from a classical violin to the 3Dvarius. Entirely adaptable and customizable, the 3Dvarius can use dimensions of your own classical violin.

Its pickup uses one sound sensor per string in order to translate all sound frequencies. Its sound sensors, located under each string, were carefully selected to accurately translate the sound frequencies.

In order to offer a maximal playing comfort, its weight distribution was optimized to re-create the comfort of a classical violin.

How do you think 3D printing will shape future music and arts?

I use 3D printing every day. But more and more as a prototyping technology for preparing new CNC or molding design. Especially for the less than 2000 euros electric violins.

Since I started, there is a lot of different things that happened between 3D printing and arts. Because of the low prices in FDM 3D printing technology, a lot of makers and musicians started to develop things with it. The future will be to my mind in using conductive or “useful” materials to produce in one time a fully functioning object.

How do you see 3D printing developing in 5-10 years from now?

New materials and low prices on SLS and metal printing technology. Also advanced education will be available in the technical studies.

How would you guide artists and future entrepreneurs to approach 3D printing?

3D printing technology is just a new way to produce objects. It has some strengths and weaknesses but you can find a lot of information on internet without any formal formation.

A final object is always produced with different manufacture technologies. The best way to use 3D printing technology is to combine it with all the present technology to extend the possibilities.

To find more

Visit website to discover the use of 3D printing technology in violins, and now in our brand new cello called “Horizon”: https://www.3d-varius.com/shop/

Contact:

Email: contact@3d-varius.com

Web: www.3d-varius.com

In 2016 Laurent Bernadac visited 3DStep in Tampere, Finland and filmed this great video during thr visit: