3D PRINTING – FREQUENTLY ASKED QUESTIONS

1. What is 3D printing used for?

Nearly anything can be 3D printed: metals, plastics, spare parts, moulds, bridges, internal organs, food, musical instruments... The main limitation in using 3D printing is our own imagination.

3D printing is used, for example, in the manufacture of industrial end products, as it allows many specific features and is cost-effective in small and medium quantities.

3D printing is a popular method for prototyping and quick product development because of its speed and low cost. Other common uses include 3D printed tools and spare parts. See the video explaining the basic ideas.

In medical applications, 3D models can help surgeons to plan surgeries, for example. 3D printing is also used to make implants, aids and appliances.

Private individuals can also use 3D printing for a number of purposes. Many items and components related to hobbies can be 3D printed, from toy figurines to car and drone parts. Ready-made 3D printable models can also be found online for household spare part needs.

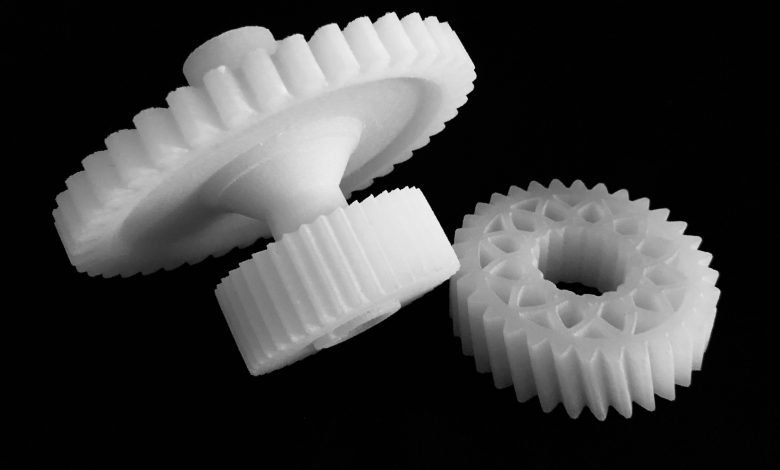

3D printed polymer components.

2. What are the benefits of 3D printing?

3D printing enables the manufacture of components that are very difficult or even impossible to make using other methods, such as highly complex, threaded or nested structures. 3D printing is the most cost-effective method for small and medium batches whenever the manufactured part has any complexity, making machining expensive.

With many products, 3D printing is also faster, cheaper and more environmentally friendly than traditional methods. Since 3D printing is an additive manufacturing process, little material waste is created. This also helps to reduce material loss.

3. Which materials can be 3D printed?

3D printing allows for a wide range of materials. The most common materials in industrial applications are metals and plastics/polymers. Ceramics, concrete and even glass can also be 3D printed.

The most common 3D printed metals include aluminium, acid-resistant steel and titanium. Popular plastics include various polyamide-based materials, which can also be glass-reinforced, as well as flexible TPU plastics.

4. Are 3D printed products durable?

The durability of 3D prints depends primarily on the technology and material used. Generally speaking, durability is never a limitation for using 3D printing in practice, however. The most common powder metallurgy techniques, for example, produce end results with practically the same durability as with traditional manufacturing methods.

3D printing professionals are able to ensure the durability of printed parts at the design stage and recommend the right material and technology for each application. When properly manufactured, 3D prints are highly durable and long-lasting.

Industrial components 3D printed for Valmet with aluminium.

6. What does 3D printing cost?

Since 3D printing is based on a digital 3D model and is therefore a tool-free manufacturing process, it is usually significantly cheaper than traditional manufacturing methods. It is most cost-effective for prototyping and with small and medium series production.

The most significant price impact on 3D prints comes from the volume of the material to be printed – the complexity of the prints is free. Customers can influence the price by acknowledging the design rules and the logic behind the manufacturing process. Service providers are happy to explain these in more detail – you can start by contacting us, for example.

7. What are the most common 3D printing techniques?

Warning: this requires a long answer!

The most common technology for industrial purposes is powder bed technology, used with both metals and plastics and utilising a laser to melt the cross-section/layer. These technologies include SLS (Selective Laser Sintering) for plastics printing and SLM (Selective Laser Melting) for metals printing. The latter is also referred to as LPBF (Laser Powder Bed Fusion). In plastics printing, another popular technology is MJF (Multi Jet Fusion) by HP, also a powder fusion technology but with the thermal energy of UV light used to fuse the cross-section.

The above-mentioned techniques are the most popular ones particularly due to their accuracy (a few tenths of a millimetre), material properties and aptitude for post-treatment in industrial applications. The end products are near-identical to those produced by traditional methods – with metals, in particular, they are practically identical.

Other technologies on the uptrend in professional use include SLA (Stereolithography) and its derivative DLP (Digital Light Processing). The common denominator is UV-curable liquid resin. The material is cured at UV light wavelengths, which allows very fine details and good surface quality in the prints. The durability of the final products is not yet on a par with powder coating techniques, but the materials are constantly evolving and heat resistance, in particular, is nowadays commendable, up to 300 °C.

Among home printers, traditional FDM (Fused Deposition Modelling) with material coiled on a wire remains the most common technique. The material is printed layer by layer on the substrate through the printer head. There are also many industrial applications of the same technology in which the size of the products is larger and the printing chambers can be heated. This allows printing more heat-resistant and demanding materials.

In full-colour printing, PolyJet technology is the most common technology, used in printers such as Stratasys and Mimaki. With PolyJet, the pieces are printed drop by drop through the printer head in a similar way as with a traditional inkjet printer. The prints are cured by UV light, and the technology allows for highly precise control over the location of each type of injected material – such as clear, colourful or backing material. Printing with this technique is slow but very accurate. The durability of the products is not as good as with powder coating techniques, but the printing produces neat and visually striking results.

Each 3D printing technique has its own advantages and limitations, so it is advisable to consult a professional for your printing needs.

8. Can anything be 3D printed?

Almost! The main limitations come from the size of the print and the choice of materials. Each 3D printing technology has its own pros and cons that can affect feasible and recommended wall thicknesses, channel sizes and post-processing, for example. However, there are far fewer limitations than with traditional methods. The right choice of materials and technologies will go a long way towards producing components that are suitable for each intended application.

9. How are spare parts 3D printed?

3D-printed spare parts are always based on digital 3D models. Once the model exists, printing is very quick. The customer may have a ready-made 3D model, or design and modelling services can be commissioned from a 3D printing partner. Sometimes a customer may only have an existing part of the desired type – either intact or broken – as a basis for 3D printing. In this case, the part is measured, scanned and reverse modelled into a digital 3D form. The spare part can then be 3D-printed either as a one-to-one replica or with also improvements made along the way.

Sometimes it is also possible to swap materials. For example, an old iron part can be replaced with aluminium at a higher quality and lower cost. After printing, spare parts may be ready for use as is or, in some cases, undergo post-treatment and/or machining before use.

Spare part for marine engine. New and original.

10. Who is 3D printing meant for?

3D printing is meant for all types of businesses, organisations and individuals. For now, the main limitation is that the method and its potential use are not yet widely known. In terms of volume, the main customers for 3D printing are large industrial companies and medical professionals.

11. What kind of business is 3D printing useful for?

Perhaps the biggest benefit of 3D printing is in the products that companies make. 3D printing can also help to create entirely new products to meet a specific customer need. 3D printing is also an important tool for product development as it allows for quick testing and thus launching finished products faster on the market. 3D printing can be used to produce prototypes and for pre-production series or finished products. Furthermore, 3D printing can be used to produce tailor-made tools for assemblers working in an assembly line. Another popular application is the production of miniature models for training and illustration purposes.

12. How are 3D prints designed?

To design 3D prints, all you need is CAD software that allows you to draw 3D models and an idea of the part to be 3D printed. If you are unfamiliar with CAD modelling and/or concerned about the functionality of the model, you can turn to a professional design service. Good end results have also been seen in situations where the customer only has an idea for a product when first contacting a service provider.

13. How to get started with 3D printing?

The best way to get started with 3D printing is to give some thought to your own needs, find out more and keep an open mind. As 3D printing professionals, we also try to keep the threshold for customers as low as possible, so feel free to contact us for more information and advice.

Here at 3DStep, we help customers get started through our Innovation Services and 3D-LEAP events, Training and Expert Services, and more. We also organise various workshops and study groups, so follow us on LinkedIn, for example, to keep posted.

14. Tell me something about 3D printing I don't already know?

3D printing is a field that allows you to explore different walks of life and see different things on an incredibly broad scale. To name a few highlights😊: We've had the chance to 3D print medieval musical instruments, instruments for oriental martial arts and splash guards for a Nissan Datsun, among other things.

Unique print works, such as these, also add to our overall 3D printing knowledge database and thus benefit our customers on a wider scale.